Warum wir handeln müssen

Die großen Herausforderungen unserer Zeit — Menschenrechte, faire Bezahlung, Umwelt- und Klimaschutz, Hunger und Wasserknappheit — brauchen eine starke Lobby. Als hanseatisches Familienunternehmen gehört es sich für uns, Verantwortung zu übernehmen und Teil einer Bewegung zu sein, die diese Probleme nicht nur mit Worten, sondern auch mit Taten angeht. Und das tun wir!

Unser Ziel: Wir möchten verantwortungsvoll und fair wirtschaften und unseren Kundinnen und Kunden einen nachhaltigen Alltag ermöglichen.

Wir nehmen die Herausforderung an!

Newsfeed

-

Kaffee

Innovation – nachhaltiger verpackt!

06.06.2023Tchibo hat eine nachhaltige Verpackungslösung für Kaffee entwickelt: Das Kaffeearoma wird geschützt, gleichzeitig wird umweltfreundlicher verpackt. Die Folien sind als „gut recyclingfähig“ zertifiziert und können nun über die Gelbe Tonne entsorgt werden.

Mehr erfahren -

Kaffee

Podcast: Erobern Frauen das Kaffeebusiness?

07.03.2023Zum Internationalen Frauentag berichtet "Kaffeewissen to go" über die vielfältigen und weiblich besetzten Positionen im Kaffeebereich. Indre als Sommelière, Saskia als Röstmeisterin und Theda als Kaffeeeinkäuferin geben Einblicke in ihren Arbeitsalltag rund um die Kaffeebohne.

Mehr erfahren -

Menschenrechte

Tchibo verpflichtet sich zu Pakistan Accord

23.01.2023Pakistan ist nach Bangladesch einer der wichtigsten Exporteure von Textilien. Der Pakistan Accord ist eine rechtsverbindliche Vereinbarung zwischen globalen Gewerkschaften, internationalen Bekleidungsmarken und Einzelhändlern, um Textilfabriken sicherer zu gestalten. Auch Tchibo hat das neue Abkommen unterschrieben.

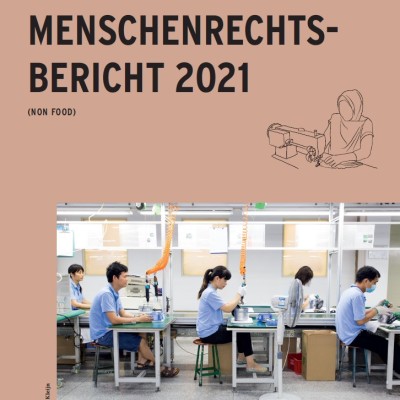

*Beispielfoto aus indischer Textilfabrik c/ Neeltje Kleijn

Mehr erfahren -

Umweltschutz

Pfandsystem für Mehrwegbecher

13.12.2022Ab sofort kann der Kaffee und Tee in unseren Tchibo-Filialen mit unserem Mehrweg-Pfandsystem auch unterwegs nachhaltig genossen werden. Für einen Euro Pfand erhalten Kund*innen einen Mehrwegbecher aus recyclebarem Material, den sie wiederbefüllen lassen und im jedem Tchibo Shop zurückgeben können.

Mehr erfahren -

Umweltschutz

COP 27

01.12.2022Sina Schoenlein war für Tchibo und unseren Logistikbereich auf dem diesjährigen Klimagipfel in Sharm el Sheikh und hat, zusammen mit anderen Mitstreitern, darüber gesprochen, wie Schiffsbelader mit der Initiative coZEV einen großen Teil ihres CO2 Verbrauchs einsparen können.

Mehr erfahren -

Allgemeines

Podcast: Rettet die Nerze!

17.11.2022In der neuen Podcast-Folge knöpfen wir uns den Pelz vor! Diesmal geht es aber nicht nur ums Zuhören, sondern auch ums Mitmachen, denn zusammen mit der Tierschutzorganisation Vier Pfoten möchten wir eine Millionen Unterschriften für ein europäisches Pelzfarmverbot sammeln!

Mehr erfahren -

Kaffee

Netzwerk Kaffeezucht gegründet

11.11.2022Mit den Herausforderungen der Klimakrise für die Kaffeewelt beschäftigt sich das World Coffee Research (WCR). In einem Gespräch mit Pablo von Waldenfelds (Tchibo) und Hanna Neuschwader (WCR) sprechen wir über die Suche nach innovativen und pragmatischen Lösungen für nachhaltigen Kaffeeanbau.

Mehr erfahren -

Kaffee

Podcast: Circular Solutions Lab

07.11.2022Wir besuchen unseren Flagship Store am Hamburger Rathausmarkt! In der neuen Podcast-Folge geht es um unverpackten Kaffee, das neue Mehrwegbecher-Pfandsystem bei Tchibo und Tchibos Circular Solutions Lab - in dem immer neue Kreislauflösungen erprobt werden.

Mehr erfahren -

Menschenrechte

Start der ersten Arbeitsunfallversicherung in Bangladesch

07.09.2022Die Regierung von Bangladesch hat in Zusammenarbeit mit verschiedenen Organisationen, Botschaften und internationalen Marken, darunter Tchibo, die erste Arbeitsunfallversicherung eingeführt. In einem Interview gibt Fatima Chowdhury spannende Einblicke über die Hintergründe.

Mehr erfahren -

Unternehmen

Community-Event im August

10.08.2022Nachhaltigkeit ist unser Community-Thema im August! Diesen Monat haben Tchibo Community-Mitglieder die Möglichkeit, mehr über unser Engagement zu erfahren, dem Nachhaltigkeits-Team Fragen zu stellen und sich mit anderen Mitgliedern rund um das Thema auszutauschen.

©Felix Mittermeier von pexels

Mehr erfahren -

Kaffee

Limitierter Privatkaffee aus Costa Rica

25.07.2022Mit unserem neuen limitierten Privatkaffee reisen wir in den Westen Costa Ricas, der beste Bedingungen für Kaffeeanbau bietet und weltweit für höchste Kaffeequalität bekannt ist. Wie alle unsere Privat Kaffees stammt der Kaffee für Costa Rica Limited ausschließlich aus zertifiziert nachhaltigem Anbau.

Mehr erfahren -

Menschenrechte

Handbücher zu Moderation und Konfliktmanagement

19.07.2022Von 2017 bis 2020 arbeiteten Tchibo und GIZ gemeinsam an der Verbesserung der Arbeitsbedingungen durch das Sozialer Dialog Projekt in Myanmar - mit der Vision, effektive Dialogstrukturen am Arbeitsplatz zu etablieren. Obwohl sich die Situation in Myanmar grundlegend geändert hat, hat das Projekt interessante Handbücher hervorgebracht.

Mehr erfahren -

Menschenrechte

Tchibo Menschenrechtsbericht 2021 (Non Food)

01.07.2022Als Familienunternehmen steht bei Tchibo der Mensch im Mittelpunkt. Wir machen uns stark für die Einhaltung von Menschenrechten. Denn diese sind nicht verhandelbar. Im Menschenrechtsbericht 2021 (Non Food) geben wir Auskunft über unsere Ziele, Aktivitäten und Herausforderungen.

Mehr erfahren -

Unternehmen

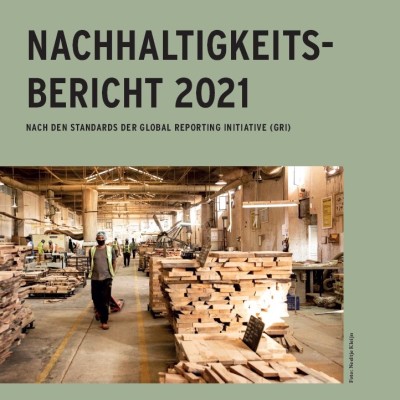

Jetzt online: Tchibo Nachhaltigkeitsbericht 2021

30.06.2022Entlang der GRI-Standards berichten wir über unsere Ziele für die kommenden Jahre, über Maßnahmen, Aktivitäten und Kooperationen, reflektieren über unsere Fortschritte und beschreiben Herausforderungen, denen wir uns im Bereich Nachhaltigkeit stellen.

Mehr erfahren -

Non Food

Podiumsdiskussion "Taking Action" auf der Greenstyle x Neonyt Lab Frankfurt

23.06.2022Sei dabei, wenn Axel Schröder (Team Human Rights) bei einem Panel der GREENSTYLE x Neonyt Lab am 26. Juni um 13 Uhr in Frankfurt über die nachhaltigen Möglichkeiten diskutiert, die wir als großes Unternehmen haben. Ein Gespräch über Schwierigkeiten, Erfolge und die Wichtigkeit von "machen statt reden".

Mehr erfahren -

Kaffee

Genuss zum FAIRlieben

02.06.2022Hinter jeder Tasse unseres BARISTA Fairtrade Kaffee stehen die Menschen, die ihn geerntet und verarbeitet haben. Umso mehr freuen wir uns, dass im vergangenen Jahr durch alle Genießer unseres BARISTA Kaffees eine Fairtrade-Prämie von fast 2 Millionen US-Dollar für Gemeinschaftsprojekte in unseren Kaffeeursprungsländern generiert wurde.

Mehr erfahren -

Non Food

Material Change Index 2021: Tchibo erneut Leading Performance Brand

01.06.2022In der jährlichen Vergleichsstudie von Textile Exchange wurde Tchibo erneut für alle Materialien (außer Leder) als überdurchschnittlich gut bewertet und als Leading Performance Brand eingestuft. Damit sind wir ein Unternehmen, das den Wandel in der Textilindustrie vorantreibt.

© Liza Summer von pexels

Mehr erfahren -

Kaffee

Neuer Qbo Premium Kaffee von der Kooperative Coopfam aus Brasilien

20.05.2022Wir freuen uns über unseren neuen Fairtrade-zertifizierten Qbo Kaffee von der Kooperative Coopfam aus Brasilien. Neben dem Kaffeeanbau ermöglicht die Farmergemeinschaft wertvolle soziale, wirtschaftliche und ökologische Projekte. Dabei unterstützen wir sie seit 2014 in einem partnerschaftlichen Projekt.

Mehr erfahren -

Unternehmen

Podcast: Tchibo & Faitrade – Lach- oder Sachgeschichten?

05.05.2022Fairtrade Gründer Dieter Overath und Nanda Bergstein, Direktorin für Unternehmensverantwortung, haben den Wandel zu nachhaltigerem Wirtschaften beeinflusst. Beide verlassen nun ihre Jobs. Also haben wir sie für eine letzte gemeinsame Podcast-Folge über Kinderarbeit, Konflikte und mutige Menschen getroffen.

Mehr erfahren -

Menschenrechte

Podiumsdiskussion: „Change Fashion – Change Politics“

13.04.2022Axel Schröder (Team Human Rights) diskutiert am 21. April um 16 Uhr anlässlich der Fashion Revolution Week Bedingungen einer fairen Textilindustrie. Verfolge die Podiumsdiskussion, um zu erfahren, wie weit die Sorgfaltspflicht von Unternehmen heute schon reicht und wo der Gesetzgeber nachbessern muss.

Mehr erfahren

Nicht 100% perfekt, aber mutig nach vorne

Was wir bisher erreicht haben

-

43.300 Farmer*innen

haben wir seit 2009 durch das Farmer*innenprogramm Tchibo Joint Forces!® in 9 Ländern mittels 20 Projekten bei der Umstellung auf einen nachhaltigeren Anbau und der Verbesserung der Lebensbedingungen unterstützt.

-

98 % unserer Textilien mit Baumwolle

stammen aus nachhaltigeren Quellen (OCS, GOTS oder Cotton made in Africa).

-

100 % Ökostrom seit 13 Jahren

an allen unseren Tchibo Standorten (Zentrale, Lager, Filialen und Röstereien).

-

134 Millionen

alte PET-Flaschen haben wir für unsere Textilien aus recycelten Materialien 2021 verarbeitet und konnten dadurch 5.500 Tonnen CO2-Äquivalent einsparen.

Quelle: Textile Exchange (eigene Berechnung basierend auf Shen L., et al. (2010) Resour Conserv Recy, 55 (1), 34-52) -

98 %

unserer Non Food-Artikelverpackungen sind recyclingfähig.

-

8 Fabriken

sind neu in das WE Programm aufgenommen worden. Gesamt waren damit seit 2008 432 Fabriken eingebunden, wovon zu Ende 2021 96 Fabriken am Programm teilnehmen. Im Jahr 2021 haben 4.900 Arbeiter*innen und Manager*innen an Aktivitäten teilgenommen.

Reicht das?

Natürlich sind wir uns der kritischen Rolle bewusst, die unser Unternehmen lange gespielt hat. Wir wissen, dass Tchibo in einigen Bereichen immer noch Teil des Problems ist. Umso wichtiger ist es für uns, dass wir unsere gestalterische, unternehmerische Kraft dafür einsetzen, jeden Tag noch mehr Teil der Lösung zu werden.

Es gibt für uns keine Alternative zu fairen Arbeitsbedingungen, Transparenz und Umweltschutz.

Der Weg dahin ist noch lang und es gilt permanent, Lösungen für wichtige Themen wie zum Beispiel Ressourcenschonung, Einhaltung von Menschenrechten und Umweltschutz zu finden. Wir sind dabei diese Lücken zügig und mit innovativen Lösungen zu schließen.